Six Sigma is simply a measure of deviation of a process from perfection. Processes adopting six sigma has a failure rate of only 0.00034%. that’s a negligible defect and near perfection. Six Sigma was developed in the 1980s by Motorola, and it has gained widespread adoption.

Companies including General Electric, Toyota, Samsung, Apple, Microsoft and Amazon have successfully implemented this and it can be used across industries to improve customer satisfaction, reduce costs as well as increase profits from studies conducted.

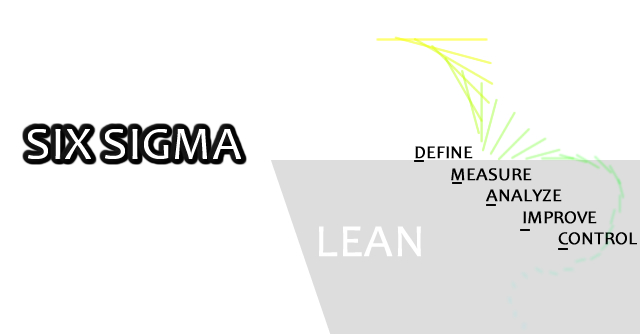

Six Sigma involve a set of methodologies and tools that business use to optimize and improve business processes. The resultant gains include reducing defects and errors, minimizing variation, and increasing quality and efficiency. The goal of Six Sigma is based on the idea that all business processes can be measured and optimized to achieve a near perfect quality, thus producing only 3.4 defects per million opportunities. Six Sigma adopts a structured approach called DMAIC (Define, Measure, Analyze, Improve, Control) to identify and eliminate causes of variation and improve processes.

Product variation and defects negatively impacts customer loyalty, customer satisfaction, performance as well as profitability.

What Is Lean Six Sigma?

Lean Six Sigma methodology combines two of the most powerful process improvement techniques: Lean and Six Sigma.

Lean, focuses on minimizing waste and maximizing efficiency by identifying and eliminating non-value-adding activities. This involves streamlining processes, reducing defects, improving quality, and optimizing resources to deliver more value with less effort.

Six Sigma adopts a statistical and data-driven approach to decision making and process improvement with the aim of reducing variation and defects. It involves defining, measuring, analyzing, improving, and controlling processes to achieve a standard and predictable results.

How to implement Six Sigma in your business

To achieve Six Sigma improvements, the causes of business process defects and variation must be identified and eliminated. Two Six Sigma sub-methodologies were developed for this purpose:

- DMAIC (Define, Measure, Analyze, Improve, Control

- DMADV (Define, Measure, Analyze, Design, Verify)

DMAIC is used to improve existing processes that are below specification;

DMADV is used to develop new processes or products at Six Sigma levels. DMADV (alternatively known as DFSS [Design for Six Sigma]), can also be applied to existing processes that require more extensive improvement.

Six Sigma implementation involve all levels of the organization, some martial arts terms have been borrowed and used in Six Sigma hierarchy:

- Executive Leadership includes the CEO and top management

- Champions, drawn from top management, are responsible for Six Sigma implementation across the organization

- Master Black Belts, identified by champions or by executive leadership, they are in-house coaches, mentors, and trainers; 100% of their time is devoted to Six Sigma to ensure business and leadership alignment

- Black Belts focus on the application of Six Sigma methodology to specific projects; 100% of their time is devoted to Six Sigma

- Green Belts are involved with Six Sigma implementation along with other job responsibilities

Lean Sigma is an industry trend in which a process is made lean through efficiency improvements before Six Sigma is applied to reduce variation.

Six Sigma Techniques

- Brainstorming

- Root Cause Analysis/The 5 Whys

- Voice of the Customer

- The 5S

- Kaizen (Continuous Improvement)

- Benchmarking

1. Gain support from top management

Like most process improvements or implementation of new systems, Six Sigma needs the support from top management. Implementing Six Sigma in your organization requires the dedication of resources (e.g. Time, human, financial, etc.).

2. Employee acceptance and induction

A successful implementation of six sigma required the support of all employees who use the system to be optimized. With training and accountability for the process, the desirable results from the implementation will be achieved. Regular communication, feedback and sharing of success stories will keep users enthusiastic about the program.

3. Have all innovative and infrastructure activities linked with the program

This really applies only to organizations that are using Six Sigma in every aspect of how they choose to do business, but it is a key factor in Samsung’s phenomenal success. Samsung chose to use Six Sigma in all areas of decision-making, including the R&D of new products. This ensured that the changes that the organization was making to its processes would maintain throughout its efforts to innovate long into the future and that improvements made would not be undone in the manufacturing of the company’s next exciting products.

4. Accuracy and fairness in the evaluation of projects

Measuring and tracking the success from Six Sigma on the company is key to evaluating the improvements that the process is churning out. Instituting transparency, accuracy with data recording and measurement, the support to include Six Sigma into every part of a business operation’s will be achieved.

5. Recognition and Reward of employees

Recognizing and rewarding of employees who have successfully made significant impact in the implementation of Six Sigma in the organization is key to maintaining the support and enthusiasm for the program. Recognizing the value employees play in optimizing business operations and how integral they are to the success of the program is key to the sustainability of the process and benefits in the form of cost savings, profitability and brand loyalty.

By the late 1990s, about two-thirds of Fortune 500 companies had started implementing Six Sigma projects; as of 2006, Motorola had reported more than $17 billion in savings as a result of Six Sigma adoption. Samsung, by 2002, also achieved cost savings, increased profits, and new product development growth to about $1.5 billion. Its Six Sigma projects conducted between 1999 and 2001 also led to a reduction in defects by 50%.

Six Sigma is indeed a strategy to truly establish a win-win situation in business process optimization, with the growth of product quality, product defects and variations are reduced significantly, employees are well involved in the process and own it. Cost savings, brand loyalty and company profitability in increased.

Page Links

- Making the Numbers Work for You: Essential Financial Insights Every Business Leader Must Know

- How to Value Your Business in Uncertain Market Conditions (Without Losing Sleep)

- Deciding Between Debt and Equity Financing (Without Getting a Headache)

- How to Craft an Investment Strategy That Balances Risk and Growth

- How to Weave ESG into Your Financial DNA Without Sacrificing Performance

- Lessons From The World's Most Trusted Companies About Financial Transparency

- Innovation Strategies for Established Businesses

- Why Recovery Matters: Understanding the Role of Rest Days for Fitness Progress

- Fitness Strategies: How to Build Lean Muscle Effectively

- Maximize Your Workout Results: Top Foods to Eat Before and After Exercise

- Real Estate Crowdfunding: A Low-Cost Way to Invest in Real Estate

- Real Estate Investing Strategies: How to Flip Houses & Build Passive Rental Income

- Mobile Payments: The Future of Fast and Secure Transactions

- AI in Finance: How Artificial Intelligence is Revolutionizing Financial Services

- The Future of Insurance: How InsurTech is Disrupting Traditional Models

- Understanding Your Financial Behavior: The Psychology of Money & How to Manage It

- Breaking Free from Debt: Proven Strategies to Achieve Financial Freedom

- The Hidden Dangers of IoT: How to Safeguard Your Connected Devices

- IoT and Agriculture: Feeding the World with Technology

- AI Investing: Best AI Stocks to Improve your portfolio

- AI Creativity : Can Machines Truly Innovate

- IoT For Business Efficiency: Key Benefits and Applications

- Cybersecurity Threats: How to Defend Against Digital Attacks

- How Carbon Credits Work: A Simple Guide for a Greener Tomorrow

- Key Risk Management Models: Understanding the Processes and Similarities

- AML Compliance -Banks : Rules and Future Practices Worldwide

- KYC: Using Blockchain for Identity Verification

- HomeBuyer's Guide to Understanding Mortgages and Rental Options in the US

- PWAs vs. Native Apps: Better Performance, Cost, and User Experience?